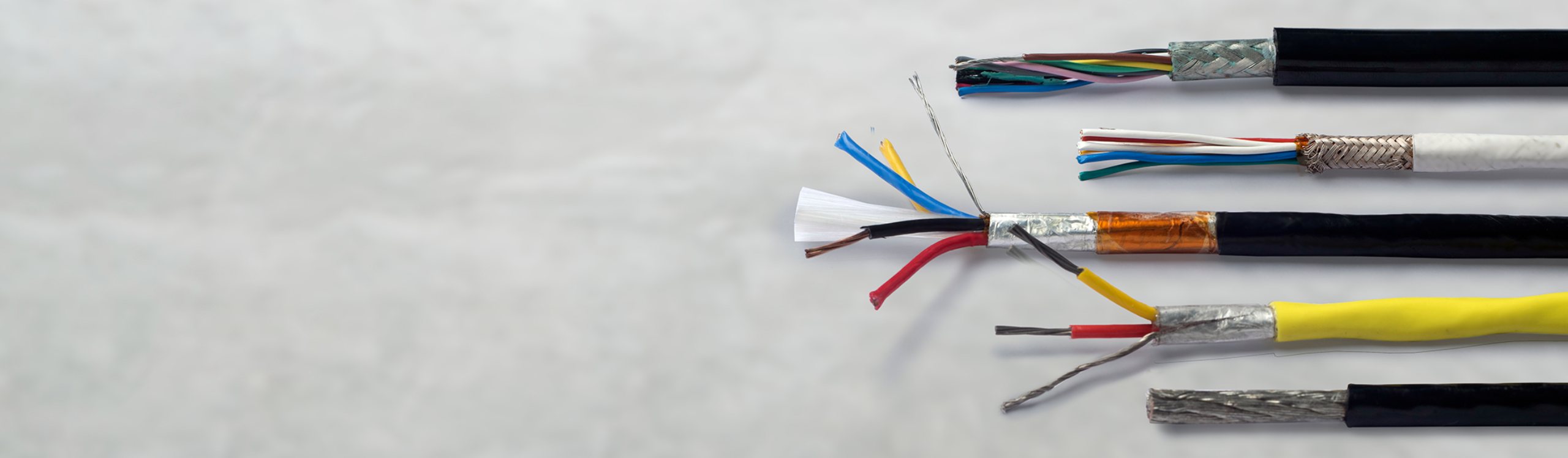

Thermo Cables takes pride in crafting high temperature cables tailored for applications in environments where both operational and ambient temperatures reach elevated levels. These cables are meticulously manufactured with a diverse selection of conductors, insulating materials, and screening materials. The choice of these components is strategically determined by the specific temperatures and conditions under which the cable is expected to perform optimally. The cables are designed to withstand extreme thermal challenges, ensuring reliable performance in environments with elevated temperatures. Thermo Cables’ high temperature cables are a testament to their dedication to providing robust and resilient solutions. These cables play a vital role in various industries where exposure to extreme temperatures is a constant, showcasing Thermo Cables’ expertise in creating reliable and durable cables for challenging operating conditions.

Single core high temperature hook-up wires & Multi core / Multi pair, Screened & Unscreened and Armoured & Unarmoured cables:

| Insulation Material | Temperature Range | Characteristics |

| Special High Temperature Yarn | -72 to 1000° C | Heat and high temperature resistance. |

| PTFE | -200° C to 260° C | Excellent chemical resistance. High temperature stability. |

| FEP | -200° C to 200° C | Good chemical resistance. Thin wall insulation due to good electrical properties. |

| PFA | -200° C to 250° C | Good chemical resistance, Thin wall insulation due to good electrical properties. Good flexibility. |

| ETFE | -150° C to 150° C | Mechanically tough. |

| XL ETFE | -150° C to 250° C | Good electric insulation, radiation resistance, ARC tracking and cold flow. |

| PEEK | -160° C to 250° C | Mechanically very tough. High temperature and radiation resistance |

| Kapton Tape | -250° C to 300° C | Very thin wall insulation. High temperature resistance. |

| Silicon Rubber | -40° C to 180° C | Flexible and abrasion resistance |

| Ceramic Yarn / Quartz Yarn Braiding | 600° C | Bad conductivity & heat and high temperature resistance. |

| Screening | Individual and / or overall with following options – – Aluminum Mylar / Copper Tape with Tinned Copper Drain Wire or – Braided with Bare or Tinned or Nickel Plated or Silver Plated Copper |

| Armouring | Steel Galvanised wire, stainless steel wire, high strength steel wire braiding |

| Standards | JSS 51034, JSS 51038, UL 1581 |

Industry & Applications

| Defence | Avionic and airframe applications provide excellent fluid/oil/moisture resistance and increased stability at higher temperature. |

| Nuclear | Resistance to high temperatures and radiations, low smoke and fire hazard behaviour. |

| Marine | Engine proximity wiring for good resistance to high temperatures,fuel oils, chemicals, saline air / water etc. |

| Communication | High frequency cp-axial cables for VHF, UHF and XHF transmission. |

| Automotive | Higher temperature, strength and durability. |

| Petrochemical | Instrumentation & control, temperature sensing, fire warning etc. |

| Steel | Cables for blast furnace, electric arc furnace, hot & cold rolling mills, steel refining faciliaties etc. |

| Power | In proximity to the turbines,boilers, ash handling etc. |

Not sure where to start? Try our products

Our solution can find thermosystems products

REQUEST A CALL BACK