Thermo Cables specializes in the production of high-quality CRD (Control and Reeling Drum) and trailing cables, which fall within the material handling cables category. Specifically engineered for deployment in conveyor machinery, these cables play a pivotal role in various industrial applications such as transfer cars, boom-stackers, side arm chargers, bulk material conveyors, and more. Their CRD and trailing cables are designed to meet the stringent demands of conveyor machinery, ensuring efficient and seamless operation.

These specialized cables find widespread application in key industry segments, including Steel Mills, Cement Plants, Docks, Power Plants, Automobile Industries, and Refineries and Petrochemicals. Their versatility makes them indispensable in enhancing operational efficiency and reliability in dynamic material handling environments across a spectrum of industrial settings.

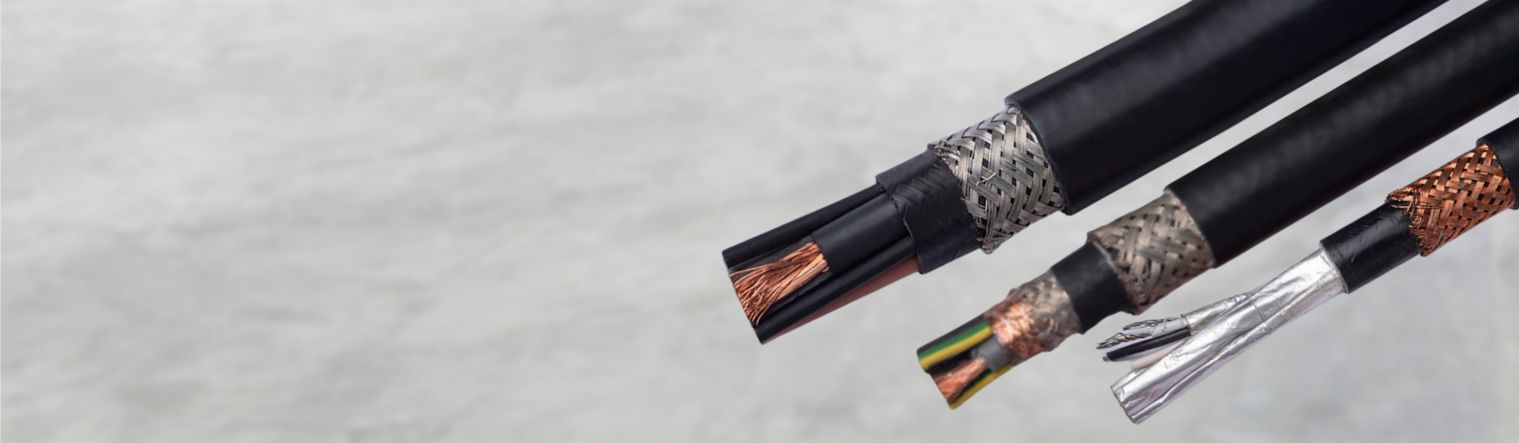

| Construction |

Single cable comprising multiple elements like power cores, control cores, signaling pairs, etc for multipurpose functions. |

| Voltage Grade | 600 / 1100 V AC |

| Conductor |

Class-5 flexible tinned or bare copper |

| Insulation | EPR |

| Screening | Tinned or bare copper wire braid |

| Inner Sheath | HOFR- Elastomer |

| Anti Kink Braid | Fabric braid embedded between inner and outer sheath |

| Outer Sheath | HOFR Elastomer |

| Features | Designed to withstand continuous reeling and unreeling Sheath materials that have a high degree of flex fatigue resistance Excellent heat, oil and fire resistant properties |

| Operating Temperature | -20° C to +90° C |

| Test Voltage | 2500 V AC |

| Bending Radius | 10 D |

| Core Marking | 1-5 cores colour coded as Green / Yellow, Blue, Brown, Black, Grey or Coloured Rubberised cotton tapes. 6 cores and above with numbered cores, with one earth core of Green / Yellow. |

| Standards | IEC-60228, IEC-60502, IEC-60332 |

Not sure where to start? Try our products

Our solution can find thermosystems products

REQUEST A CALL BACK